- DIAMOND SA | Fiber Optic Assemblies

- High quality fiber optic components

- Connectors & Adapter

- High Power & Polarization Maintaining

- High Power injection connector

Connectors for high power injection

Step-index fibers have a uniform core with one refractive index and a uniform cladding with a smaller refractive index.

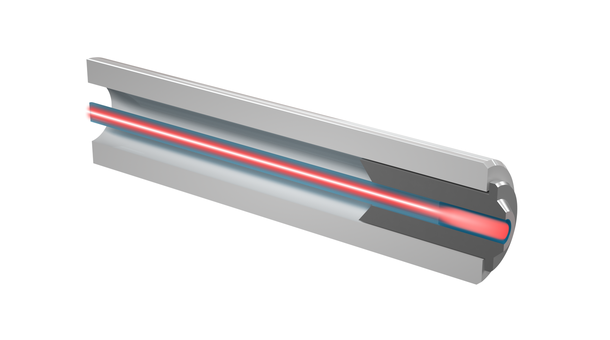

A step-index fiber is a glass fiber characterized by a uniform core with one refractive index and a uniform cladding with a smaller refractive index. The fiber owes its name to the fact that this increase in refractive index between core and cladding is in steps. Due to the large core diameter (large core), several modes of the light wave can propagate in the step-index fiber. Due to the large mode field diameter (fiber core), different propagation times of the individual modes occur, which means that information can only be transmitted over short distances. Because of the easy coupling (light injection) and the transport of high light power (light transport), these fibers are used in material processing or in medicine.

Step-index fiber at Diamond - Power Solution Injection (PSi)

Diamond F-SMA PSi connectors are mainly used for the transmission of medium to high laser energy in industrial, medical, and military applications. These connectors are intended for use at the focal point of a laser system to couple and transmit maximum light energy, as they can withstand up to several hundred watts of power, among other things. In addition, they can also be used on the laser output side. The ferrule and connector bodies are made of thermally conductive materials that ensure better heat dissipation compared to standard multimode connectors. The free-standing fiber technology prevents epoxy resin from burning and melting the ferrule.

F-SMA connectors are available in mode guider and mode stripper versions. The mode guider version transmits all modes, including those in the cladding. Heat generation is thus minimal, and maximum optical power is available at the cable exit. It is therefore mainly used in conjunction with fibers with a low refractive index coating or double cladding fibers. The Mode Stripper version removes unwanted cladding modes directly in the connector, and is used when small spot diameters and low numerical aperture are required.

Advantages of our connectors

- Free-standing fiber technology

- Copper ferrule

- Optimized heat sink for natural and forced convection

- For MM fibers from 100 μm to 1000 μm

- Thermal face polishing

- AR coating for lower reflection